Solution Provided | Detailed Engineering Design for an Apron Feeder System

Disciplines | Mechanical Engineering, Civil and Structural Engineering, Electrical Engineering

Carnac were engaged to provide detailed engineering design for an Apron Feeder and Rock Box Replacement, Apron Feeder and Skirt Installation, and Conveyor Support Structure Modifications.

A set of existing Apron feeders were upgraded to units capable of higher throughput. This resulted in the following adverse effects:

The existing rock boxes were choking with product;

At the loading points where the two apron feeders discharge onto the Conveyor, the impact beds and support stringers were being adversely affected by this additional loading, resulting in drumming (banging) and cracking of the conveyor structure; and

Spillage between the draw down chute and apron feeder pan.

Carnac provided the client with detailed engineering design to address these issues as follows:

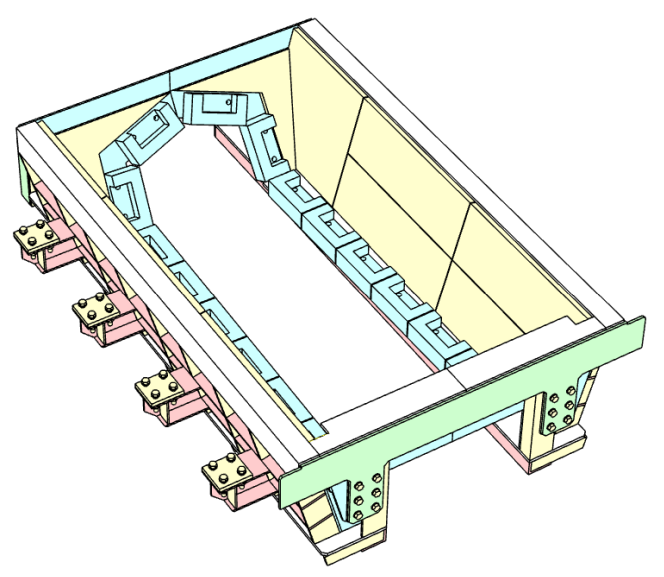

The final design for the Apron Feeder and Rock Box Replacement contained inclined Arcoplate walls, reduced shelf width, self-relieving discharge and head-end cutout. The design did not amplify shear intensity or belt wear on the conveyor compared to the current levels;

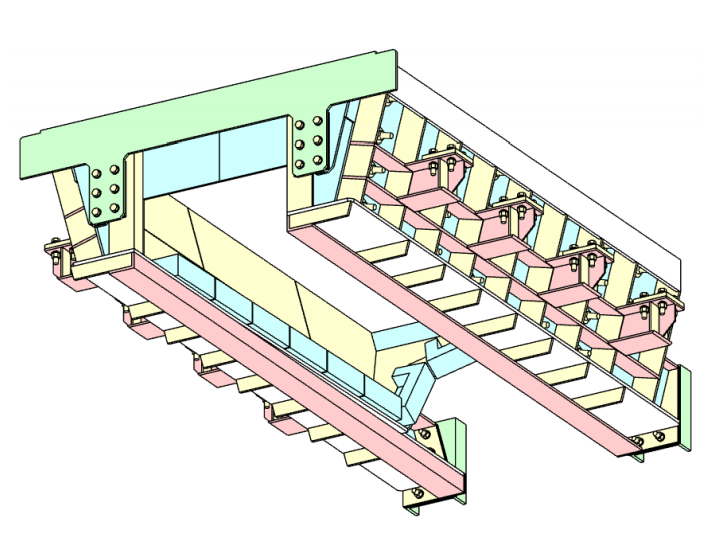

Design of a lower stack-height sealing system to reduce spillage and maintenance; and

Braces were designed for strengthening and stiffening the Conveyor Support Structure, in order to handle the increased apron feed throughput.